Categories: Tags: sheathing bridge equipment for-wood-timber-builders

Description

Triad’s Open Stringer Saw (OSS) was designed to increase productivity and cut a perfect stringer every time. The OSS is powered by two soft start motors and uses two 30”x 80 tooth carbide tipped blades. The OSS is PC controlled and has automatic indexing and cutting. An in-feed and out-feed roller conveyor comes as standard equipment with the unit.

Specifications*

-

Electrical …

Categories: Tags: screw sheathing bridge for-steel

Description

Automate and accelerate the (formerly labor-intensive) sheathing of your wall panels with the precision Triad Screw Bridge. Triad’s Screw Bridge handles the precise demands of automated fastening. Every fastening screw can be driven straight, and precisely sunk to fasten the material.

The Screw Bridge has separate on/off switches for each screw gun, to turn off the guns when …

...Read Article

Categories: Tags: panelization framing bridge for-wood-timber-builders

Description

Triad’s Stud Stitcher Bridge is a one-man framing operation designed for use with the Gen II Framing Table. The operator guides the Stud Stitcher Bridge over a clamped wall and the bridge is ready to fire. The Stud Stitcher clamps the stud horizontally and vertically and places four nails (two on each side of a 2x4 wall) simultaneously fastening both plates and stud. The operator …

...Read Article

Categories: Tags: routing sheathing openings bridge for-steel-stud-builders for-wood-timber-builders

Description

Triad’s Router Bridge allows you to router your wall panel openings, such as windows and doors, as an integral part of your process. The dedicated router bridge can be placed over a Triad Framing Table (in a single table workcell system) OR over a Triad Sheathing/Squaring Table (in a two table workflow, which allows your framing table to be working on the next panel, for increased …

...Read Article

Categories: Tags: sheathing bridge material-handling for-modular-builders

Description

The Triad Material Bridge is designed to move along the table and hold material for the wall panels. This allows the operator to place the material “on the fly” and eliminates extra walking.

The bridge is guided by a track, squared to the table. Adding the Material Bridge to any wall panel table saves labor for faster production times.

Capacity

- 10,000 lb. weight capacity …

Categories: Tags: sheathing bridge for-wood-timber-builders

Description

The ultimate sheathing bridge, for precision, versatility, automation, and SPEED

The industry is sitting up and taking notice of the incredible Triad ProFusion Bridge. It is so popular that we are often building sold units two or three at a time. Why? It’s FAST and accurate. Six separate high-capacity nailing tools (front side and back side) intelligently divide the work using …

...Read Article

Categories: Tags: multi-tool sheathing bridge for-wood-timber-builders

Description

The Trident Sheathing Bridge is a very popular sheathing bridge choice. Why? 3 high-capacity nailers giv builders flexibility without compromising speed and efficiency, while at the same time significantly reducing tool cost over traditional bridges nailing bridge. Can be operated in your choice of Fully Manual mode, Semi-Automatic mode, or Automated (virtually unmanned) operation.

The …

...Read Article

Categories: Tags: sheathing bridge

Description

A Triad MultiBridge gives you TWO gantries with your choice of combined functionalities. So many great options! And the MultiBridge can be made to fit most Triad Framing Tables and/or Squaring-Sheathing Tables.

For example: A wood-timber builder might choose a Trident Bridge on one gantry, and a Router Bridge on the second gantry. That means the ability to nail the sheathing onto the …

...Read Article

Categories: Tags: sheathing bridge equipment for-wood-builders

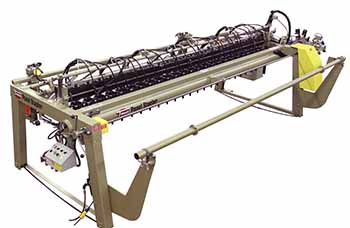

Features

- Custom built for 8’ to 16’ wall heights

- Push button controls for one person operation

- Single or double tool bars available

- Tools can be mounted 6", 8", 12" on center

- Tool bar designed to shift 3", 4", or 6" for seams

- Dual pressure selector switch for varying material densities

- Each tool is independently spring-loaded to adjust for material …